SMPS vs PSU—Which Power Supply Performs Better in Efficiency and Stability

When choosing a power source for electronic systems, professionals often compare SMPS (Switched Mode Power Supply) and PSU (Power Supply Unit). While both are designed to convert electrical energy for device operation, they differ significantly in structure, performance efficiency, and usage scenarios.

What Is a PSU (Power Supply Unit)

A PSU is the backbone of any electronic system, responsible for converting alternating current (AC) from the wall outlet into direct current (DC) that components can use. Traditional PSUs often use linear conversion, which, although reliable, tends to waste more energy as heat and requires bulkier components.

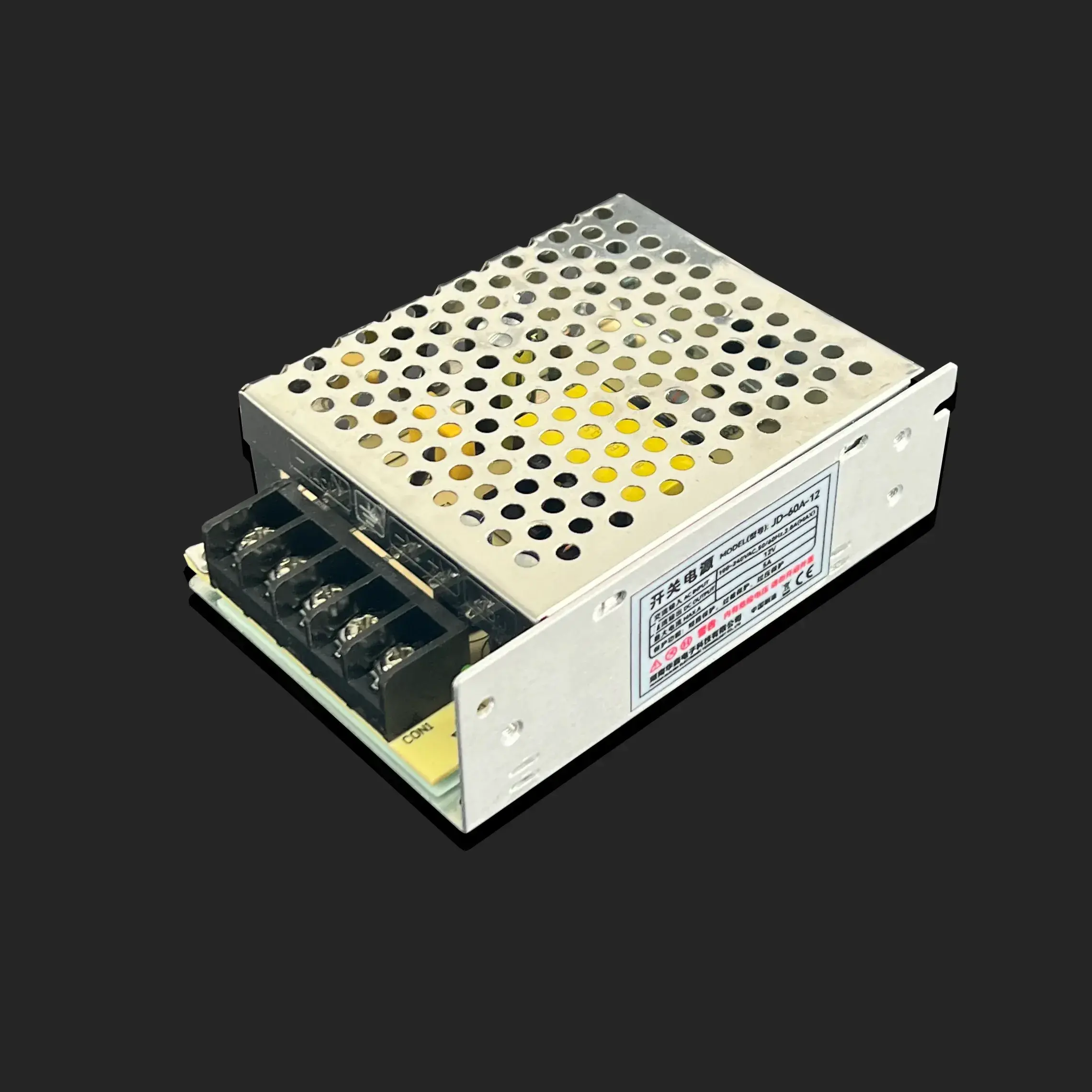

What Is an SMPS (Switched Mode Power Supply)

An SMPS, on the other hand, is an advanced type of PSU. That uses switching regulators instead of linear ones. This allows it to convert power more efficiently and compactly. SMPS units are now common in networking gear and high performance computers, where efficiency and reliability are key.

Key Differences Between SMPS and PSU

While both systems power devices, their internal design and performance make them suitable for different needs.

Efficiency and Energy Consumption

SMPS typically achieves 80–90% efficiency, compared to 60–70% for traditional PSUs. Less heat generation means lower cooling costs and longer equipment life.

Size, Weight, and Heat Dissipation

SMPS units are designed with switching technology, allowing them to be more compact and lightweight. In contrast, PSUs rely on large transformers and heat sinks, which add bulk and weight to the system. What’s more, many SMPS models feature integrated overload protection and thermal management functions.

Voltage Regulation and Power Output

SMPS provides stable voltage output even with input fluctuations. PSUs are less efficient at voltage regulation, particularly under variable load conditions.

Maintenance and Durability

SMPS costs slightly more upfront but offers better long-term ROI due to reduced energy loss. PSUs are cheaper initially but require more maintenance and energy over time.

Real World Applications of SMPS and PSU

Industrial and Commercial Usage

SMPS is preferred in data centers, telecom systems, and manufacturing plants for its efficiency, compact size, and heat management. PSU remains relevant in older industrial equipment where voltage precision is less critical.

Home and Consumer Electronics

SMPS powers devices like TVs, routers, and computers. PSUs are used in simple electronics where high efficiency isn’t a priority.

Finding the Better Option Between SMPS and PSU

If your goal is performance, the SMPS is the clear winner. For professional buyers, it can reduce power consumption by up to 30% and enhance reliability. However, for budget-sensitive applications where efficiency isn’t crucial, a traditional PSU might suffice.

The right choice ultimately depends on your application requirements and energy priorities.

Frequently Asked Questions (FAQs)

1.Is SMPS the same as a PSU?

No, SMPS is a type of PSU that uses switching technology for higher efficiency.

2.Why is SMPS more efficient than PSU?

Because it uses high-frequency switching to minimize energy loss and heat dissipation.

3.Does SMPS require special maintenance?

Not generally. It’s designed for long-term, low-maintenance operation.

4.Which is better for high-performance computers?

SMPS, due to its stable voltage and energy efficiency.

5.Is PSU obsolete now?

Not entirely. PSUs still serve in low-demand or legacy systems.

SMPS has clearly outperformed traditional PSU systems in efficiency, durability, and overall performance. For professional buyers, using SMPS means lower operational costs and fewer maintenance issues.

Ready to upgrade your systems? Choose a high-quality SMPS from WHOOSH to future-proof your operations and enhance energy efficiency.

EN

EN AR

AR NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT KO

KO PL

PL PT

PT RU

RU ES

ES TL

TL IW

IW ID

ID UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS SW

SW AZ

AZ UR

UR BN

BN KK

KK